Analysis of the construction phases and bridge assembly project.

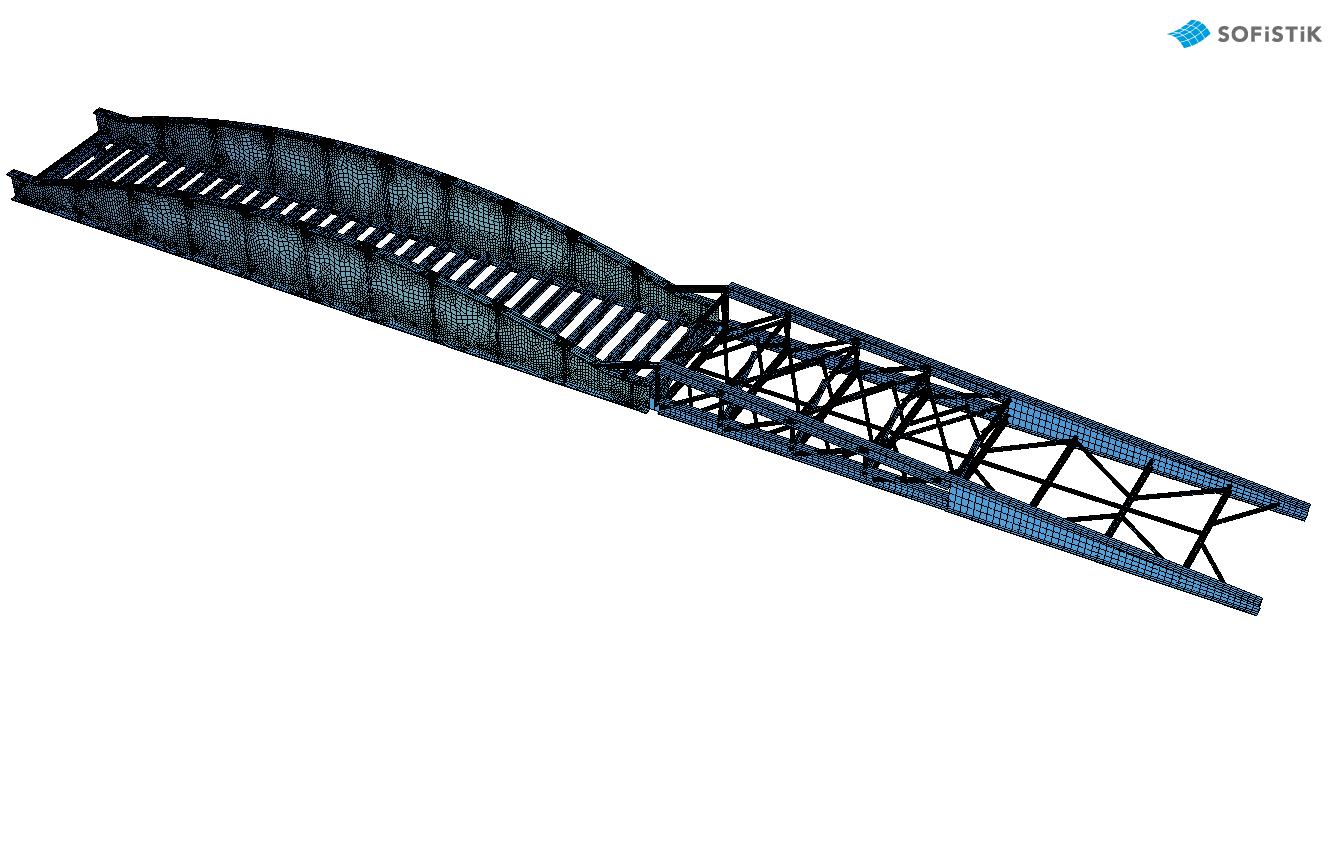

FEM analysis of the bridge structure during the various phases of launch and design of the auxiliary construction site structures

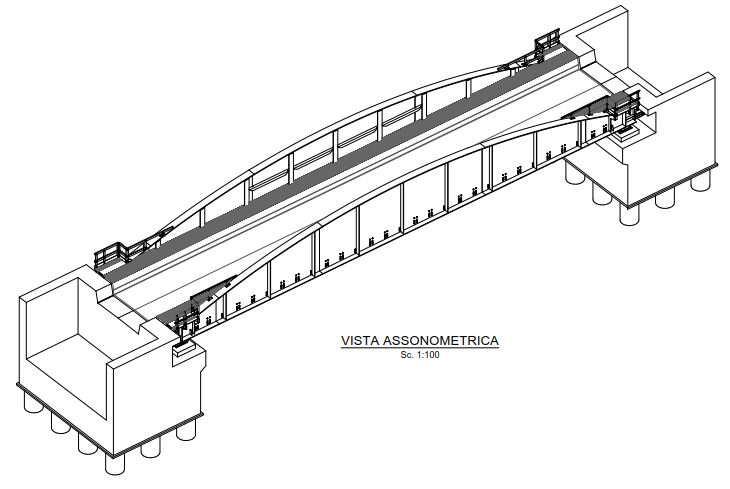

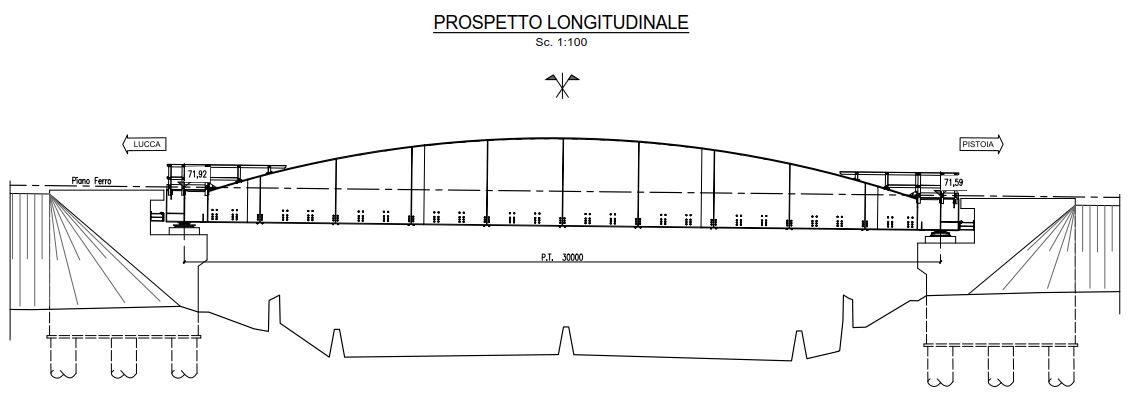

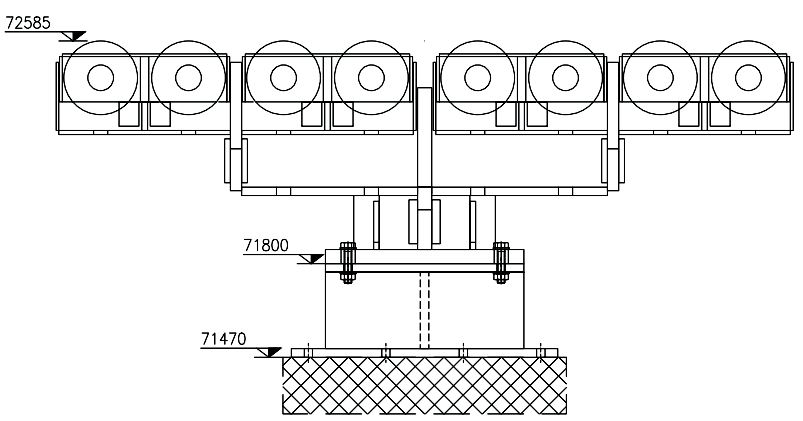

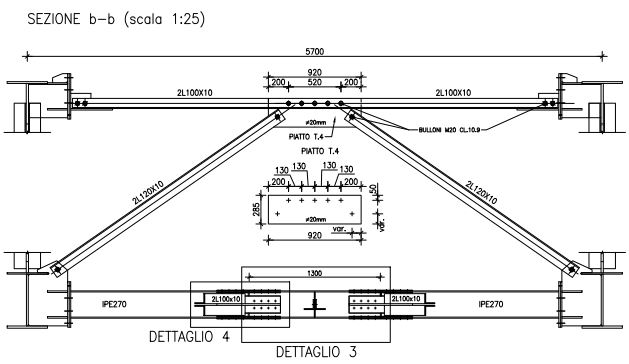

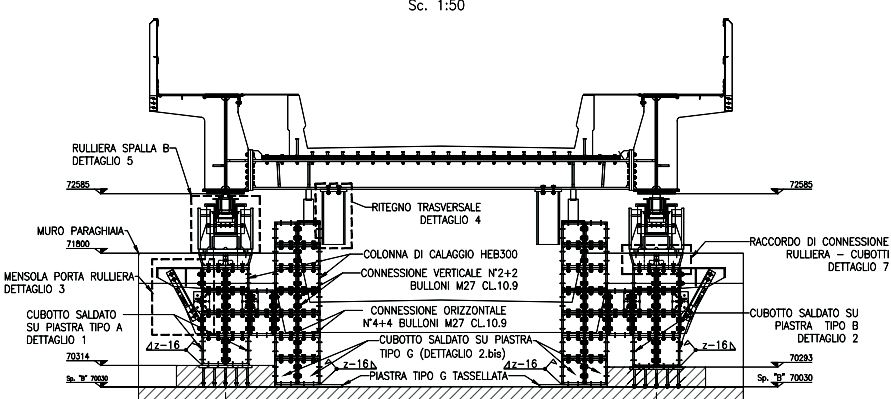

The bridge is made up of a steel deck, according to a simple support scheme, formed by two main beams, of variable height according to a parabolic profile, connected to each other at the height of the lower platbands by means of crosspieces placed at a distance of 1.00m . The total span of the beams is 31.40m, with support points placed at a distance of 30m, while the distance between them is 5.70m; the beams have a minimum height at the support of 1285mm and a maximum height in the middle of 3510mm and are made of a welded composition with an upper flange 450x40mm, a lower flange 600x30mm and a variable thickness core of 30, 25 and 20mm. The running beams are made with HE400A merchant profiles, while those in correspondence with the supports are made in a welded composition of the PRS 300 * 25/340 * 20/300 * 25 type. The trellis of beams is completed with a 30mm thick sheet metal bolted to the crossbars, made integral with the above reinforced concrete box. by means of specific pegs. The support devices are in steel – Teflon with an inverted spherical cap, according to the type used at RFI. For the assembly, the launch of the tip was planned with the aid of a forearm

Utilizzando questo sito web si acconsente all'utilizzo di cookies in conformità alla nostra politica sui cookies. Informazioni OK